Choose Lonnmeter for accurate and intelligent measurement!

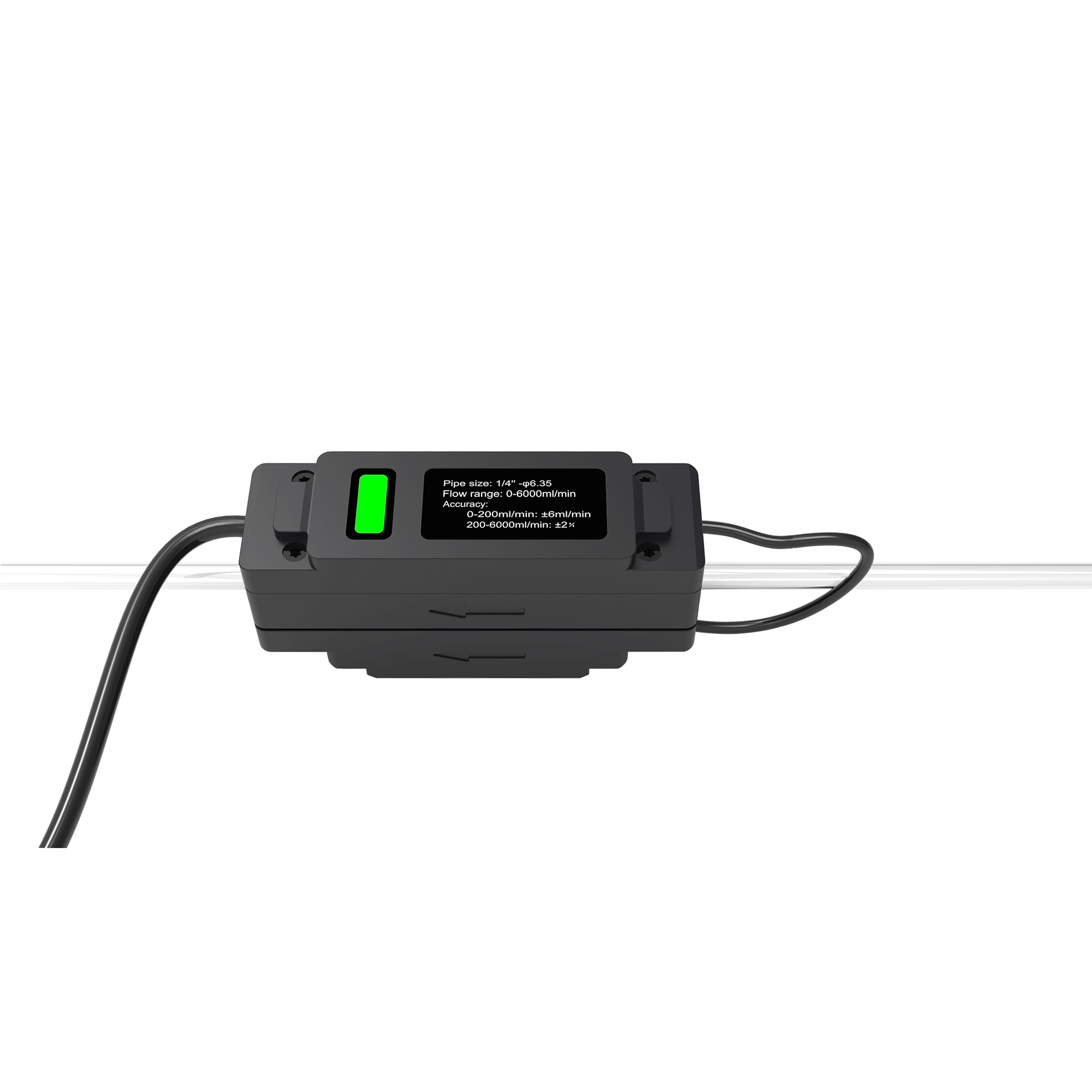

Clamp On Ultrasonic Flow Meter

Clamp On Ultrasonic Flow Meter

Product Highlights

✤Flexible and non-invasive installation

✤No moving and wetted parts

✤No measurement drifting and pressure drop

✤Relatively high turndown ratio.

✤Versatile for measurement of liquids, gases and steam

✤Unmatched accuracy & long-term reliability

Lonnmeter offers ultrasonic flow meters to thousands of customers worldwide over the last decades, which have a huge spectrum of applications in a variety of fields.

Applications

The clamp-on ultrasonic flowmeter is proved to be the most accurate meter to dealing with special properties of the liquids involved and difficult-to-reach measurement point. Such ultrasonic clamp-on flow meters are useful in testing aircraft hydraulic systems, in which viscous and corrosive liquids are difficult to measure with traditional meters. Moreover, fuel oil and other fluids in the aerospace sector could be measured, too.

The ultrasonic flow meter is ideal in chemical industry for new instrumentation, especially effective to avoid shutting down and potential dangerous leakage of plant commissioning or the extension of the product facilities. In above conditions, flowmeters are essential to be resistant against corrosive fluids and withstand to wide-range temperatures.

Efficient manufacturing and improved productivity grow important nowadays, given increased global competition, environmental regulations and rising cost of raw materials and energy. It contributes to higher efficiency in plant optimization for easy to use and offering instant readings.

Semiconductor Industry

Food & Beverage

Medical Dosing

Aircraft Hydraulic System

Chemical & Petrochemical

Manufacturing & Processing

More from Our Portfolio

Clamp-on flow meters are often applied in many areas of marine engineering like shipbuilding and ship maintenance. Vessels feature countless meters of pipework carrying fluids like water, wastewater, cooling liquids, fuel and hydraulic oil.

Ideal choice for demanding measurement requirements and challenging environmental areas in oil & gas industry, where toxic and hazardous gas or fluids are found inside the pipe.

Excellent equipment for reliable and accurate metering for energy supply like nuclear fission, burning fuels or water power. The invaluable non-invasive flow meter works in different generation processes vary in size and type.

The non-invasive water flow meter is easy to install for handling of extensive pipe networks with large diameter. It can be used for permanent installation on pipelines when an invasive flowmeter is not economically viable.

Manufacturer Advantages

✤Comprehensive and sophisticated solutions

✤Tailored solutions based on specific requirements

✤Cost-effective and flexible quotation mechanism

✤High productivity and adequate stock to fulfil quantity needed

✤Longer product lifespan and fewer maintenance issues

✤IoTs and connectivity to central control system