Choose Lonnmeter for accurate and intelligent measurement!

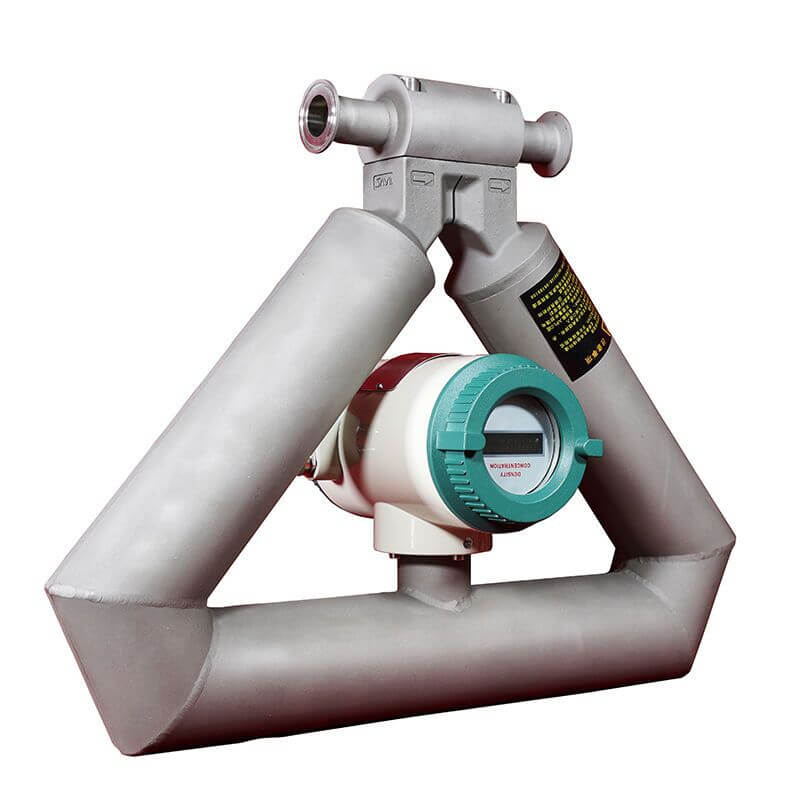

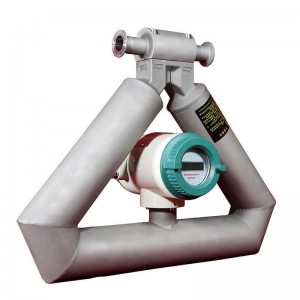

Coriolis Density Concentration Meter

Coriolis Density Meter

Oil refining and blending of petrochemical industry are typical application of the Coriolis density meter. At the same time, it's an ideal option for viscous fluids like vegetable oil and beverages containing sugar. Fine chemical engineering often take the good advantages of inline concentration meter for accurate liquid measurement, such as weak acid- or alkali-based solution contacting with anti-corrosion parts directly. It also works in industries like paper manufacturing, wine production, salt processing, printing and dyeing.

Compared to similar inline density meters, it outperforms than others in viscous fluid measurement, especially in dirty or adverse working environments. It's maintenance-free and integrated into pipelines to provide continuous density and concentration monitoring.

Highlights

Integrated plug-and-play design

Continuous density monitoring

No moving parts and less maintenance

Customizable material of parts contacting with fluids (316L or titanium)

Feature built-in temperature sensor

Attentions

◮Applicable to places without shock and vibration;

◮No frozen mediums for fear of sensor damage;

◮Avoid direct contact with corrosive medium;

◮Prevent slag from accumulating in the tank;

◮Do violent throwing or knocking;

◮Do not measure highly corrosive liquids;

◮Do not exceed nominal pressure in operation;

◮Ban pipeline welding when installing the density meter.