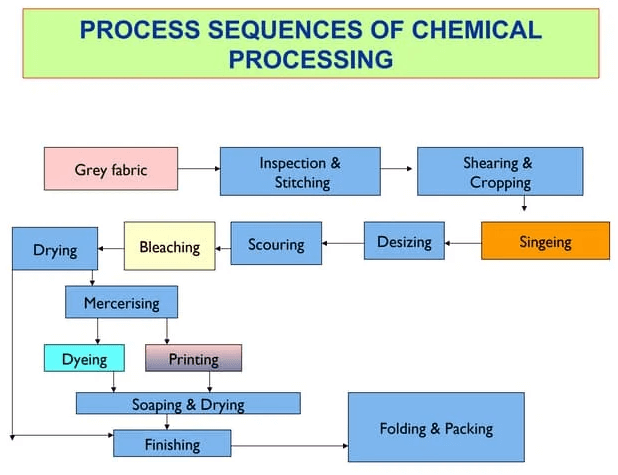

Lonnmeter is one of the competitive manufacturer of inline density meter. The printing paste density meter enables momentary density monitoring breaking away from frequent manual sampling and interruptions in the process flow. It works in additive addition, printing paste distribution, desizing, sourcing and bleaching stage in textile dyeing and printing.

Conventional manual density measurement fails to monitor dye density in real time, resulting in color differences and blotches in printed fibers or textiles. Inaccurate density measurement leaves negative effects on clarity, vibrancy and durability of printed patterns.

Drawbacks of Inaccurate Density Measurement

In addition to the above negative impacts on product quality, inaccurate density measurement often result in over-dosing of pigments and chemical auxiliaries to reach targeted effects, increasing cost of production and resource wastage. Excessive use of dyes and auxiliaries makes treatment a more challenging task and causes substandard discharge. Healthy of operators exposed to such operational conditions is threatened for flammable, explosive or toxic properties of dyes and auxiliaries.

Manual sampling from numerous measuring points fails behind real-time fluctuations for changing process conditions. Furthermore, errors typically occurred for incorrect measuring points and deviations in readings.

Applications of Inline Density Meters

One international group integrates our in-line density meter into their chemical distribution and control system, realizing precise transmissions and distribution of pigments as well as auxiliaries in an efficient way. So that density, concentration and viscosity of dyeing solutions and auxiliaries reach preset standards, improving precision of chemical auxiliaries and entire efficiency of the production line.

Merits of Automatic Dyeing Density Meter

Improvement in product quality and precision control. The advanced technologies and meter enable precise measurement of chemical dyes, avoiding technical problems caused by manual measurement like color differences and insufficient color fastness. Batching is able to execute according to preset process formulas, ensuring the accuracy and repeatability of each batching.

Automation processes reduce manual interruptions, improving production efficiency and shortening production cycle greatly. For example, it can save more than 80% of manpower and shorten process time by more than 20%.

Through accurate measurement and intelligent control, excessive use of dyes and chemicals is avoided. It can save 5%-25% of dyes and chemicals and reduce production costs by precise density monitoring and intelligent control.

Enclosed pipeline avoids leakage and volatilization of dyes and chemicals during transportation after installation of an online density meter. It reduces environmental pollution, and at the same time reduces the risk of operators' exposure to dyes and chemicals and improves production safety.

Recommended Fork Density Meter

Post time: Jan-08-2025