Chlorine Flow Meter

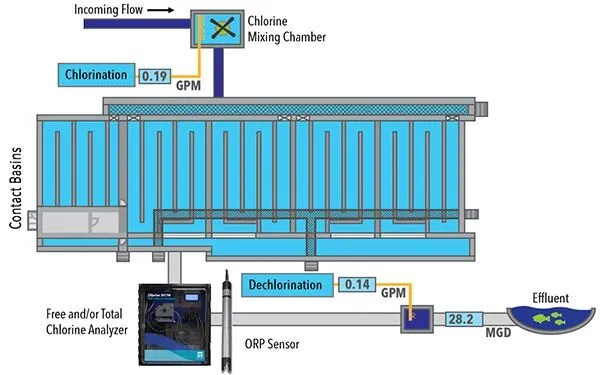

In order to provide safe and reliable drinking water, chlorine disinfection is the common method widely used in municipal water systems to eliminate harmful germs. Therefore, effective chlorine flow measurement is crucial in water treatment plants. Under- and over-injection of chlorine pose risks to public health and increase cost of treatment.

Explores the importance of chlorine flow measurement in municipal water treatment, and discover cost-effective solutions to improve efficiency and safety of water treatment.

Importance of Chlorine in Water Treatment

Chlorine, renowned as an effective disinfectant, is usually used in water treatment for sterilization. Either gas or liquid chlorine weighs in keeping safe and clean of drinking water. Nevertheless, improper chlorine disinfection may result in two types of outcomes: over-chlorination and under-chlorination.

The former wastes too much expensive chlorine gas, causing unpleasing taste or odor, and needs costly residual removal. The latter gives rise to inadequate treatment and higher risks of re-treatment. For the purpose of reliable and accurate measurement of chlorine in water treatment, both liquid chlorine flow meter and chlorine gas flow meter are inevitable devices in water treatment plants.

Contact the leading chlorine flow meter suppliers for more details and requirements from you.

Challenges in Chlorine Flow Measurement

There are several challenges occur in chlorine flow measurement of water treatment plants, including but not limited to:

No.1 Inaccurate Measurement

Conventional instruments like rotary meters or differential pressure (DP) meters fail to providing precision real-time monitoring, especially in conditions of low flow rates. This causes inconsistent chlorine usage and unstable control on dosing.

No.2 Limitations on Turndown Capability

Chlorine flow rates differ obviously relying on demanded water. Rangeability of conventional flow meters fail to span over the necessary range from both high and low flow rates accurately.

No.3 Transition of Flow Conditions

The flow of chlorine often turn from laminar to turbulent in chlorine processing systems. The accuracy of flow rate measurement decreases with the velocity of measuring flow.

NO. 4 Corrosive Nature

The target flow meter should be made from durable and anti-corrosive internal coating to withstand its corrosive nature.

No.5 Confined Spaces in Water Treatment Plants

Water treatment facilities are typically installed in confined spaces, in which few straight-pipe runs for space-saving. Those intricate pipelines cause distortions in flow profiles and compromising the overall treatment accuracy.

Crucial Requirements of Chlorine flow Meters

There are all listed tips should be considered prior to select a right flow meter in water treatment lines, including wide turndown ratio, high accuracy, corrosive-resistant coating, compact design and simple installation. Looking into above property one by one and see how could one benefit from a chlorine mass flow meter.

Wide turndown ratio allows operators to adjust settings to reach the purpose of handling both low and high flow rates with long-standing reliable accuracy. Inert coatings and durable materials are all essential properties to keep accuracy and reliability of long-term measurement.

Compact size of flow meter make it runs in confined spaces possible. On-site display and remote display bring much convenience and streamline daily operations significantly. So it's necessary to compatible with modern control systems.

Thermal Mass Flow Meter

Recommended Meters to Chlorine Flow Measurement

Thermal mass flow meter is an ideal option given all above factors in chlorine flow measurement, an effective meter for chlorine gas control. Thermal dispersion technology is adopted to flow measuring directly. In other words, additional temperature and pressure compensation is not necessary in water treatment lines.

Chlorine flow measurement is staying in excellent accuracy, even in transitional conditions. High turndown ratios allows operators adjusting settings to meet up needs of low flow rates dexterously. It's perfect compatible with upstream flow conditioners to ensuring a uniform flow profile after clearing off swirl and velocity distortions. This is particularly beneficial in systems with inadequate straight-pipe runs.

Accurate chlorine flow measurement is a cornerstone of effective water treatment plant operations. By addressing challenges such as poor accuracy, limited turndown, and corrosive environments, modern flow meters enable plants to optimize chlorine dosing, improve water quality, and reduce operational costs.

Adopting advanced solutions like thermal mass flow meters, flow conditioners, and precise calibration techniques ensures safe, efficient, and reliable chlorine disinfection processes. With proper chlorine flow management, water treatment plants can continue to provide clean and safe drinking water to their communities while minimizing waste and costs.

Post time: Nov-22-2024