co2 Mass Flow Meter

Accurate measurement consists the backbone of efficiency, precision and sustainability in numerous industrial fields, environmental sectors and scientific processes. CO₂ flow measurement is the core of processes influencing our daily lives and planet, spelling the significant difference between successful and costly inefficiencies.

General States of Carbon Dioxide

Carbon dioxide exists in four states -- gas, liquid, supercritical and solid in total for varied temperature and pressure conditions. Nevertheless, those four states present distinct processing challenges to reach specific handling and measurement challenges.

Gaseous carbon dioxide is widely applied in greenhouse enrichment, fire suppression systems and even in food packaging for long-term preservation. Liquid carbon dioxide is achieved by subjecting to high pressures and low temperatures, being indispensable in applications like beverage carbonation, refrigeration and high-pressure transportation.

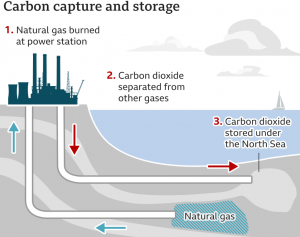

The supercritical co2 is found applied in enhanced oil recovery, carbon sequestration and as a solvent in extraction processes; solid co2, known as dry ice, is commonly used in cooling, preservation, special effects and industrial cleaning.

Challenges in Measuring co2

For the sake of its unique distinct in various conditions, there are numerous technical challenges in flow measurement, especially precise measurement for gaseous co2. It requires constant adjustments to reach processing standards for its compressibility and temperature sensitivity. Even small errors in measurement may cause tremendous discrepancies.

High-pressure environments and the risk of cavitation may undermine the performances of traditional flow meters. Besides, impurities and phase transitions in transport are causes of errors in case a wrong flow meter is installed in industrial measurement.

Density and viscosity fluctuation leave accurate measurement more complicated in supercritical systems, in which instruments need to be adapted to dynamic properties and maintained to required precision.

Functions of CO₂ Mass Flow Meters

The carbon dioxide gas flow meter is a dedicated device designed to monitor mass flow of co2 through a system. The purpose of such meters lie in keeping accuracy of flow measurement in varied temperatures and pressures. They are applied in many industries, ranging from food and beverage to oil and gas. Therefore, operators are able to monitor and control CO2 usage, reduce waste and meet up with strict environmental and processing standards.

Working Principles of CO₂ Mass Flow Meter

A carbon dioxide flow meter measures the flow passing through a system directly or indirectly, namely direct or indirect mass flow measurement. Just as its name implies, direct mass flow measurement monitor the flow rate according to physical properties of CO2; indirect flow measurement calculate mass flow via indirect parameters like fluid density and flow conditions.

For instance, Coriolis mass flow meter and thermal mass flow meter are all devices for direct mass flow measurement, measuring inertia and heat dissipation of passing flow. Differential pressure (DP) flow meter is an example of indirect measurement, inferring mass flow through the pressure drop. In general, indirect measurement applied in industrial processing requires temperature and pressure compensation for higher accuracy.

In summary, indirect mass flow meters infer flow rates through secondary parameters like pressure, temperature and volume. In spite of their versatility and cost-effectiveness, they are junior to direct mass flow meters in precision. On the contrary, direct mass flow meters measure flow rates directly, no needs for any temperature compensations. So thermal or Coriolis meters are suitable for dynamic or high-precision applications.

Recommended Products for CO2 Measurement

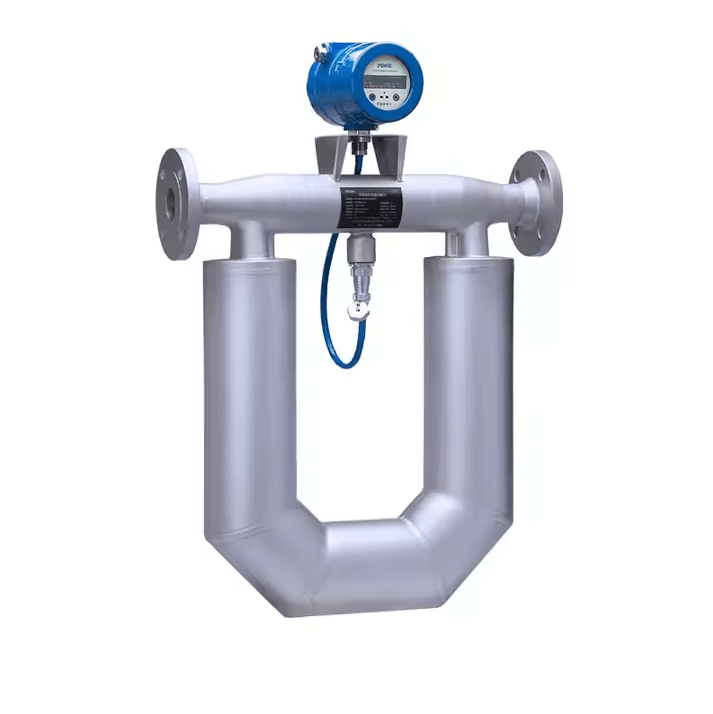

Coriolis Flow Meter for CO2 Mass Flow Measurement

The Coriolis mass flow meter works on the principle of inertia, which is produced by the moving mass passing through vibrating tubes. The phase shift is the function of the mass flow rate, reaching purposes of smart and accurate measurement.

Product Features:

✤Outstanding accuracy within 0.1%

✤Versatile for both liquid and gaseous CO2 measurement

✤Independent of temperature and pressure fluctuations

✤ Real-time reliable density monitoring

In addition to above features, it still works in cryogenic CO2 flow measurement for its liquid status at low temperatures, especially specializing in withstand to extreme conditions. It could be calibrated to reach certain accuracy in despite of rapid changes in temperature.

Thermal mass flow meters work through introducing heat to gas flow and measure heat difference between two sensors. This temperature drop is caused by endothermic reaction as CO2 passes from one sensor to the other. The flow rate of gas could be calculated through that of heat loss, which directly correlates to the gas flow rate.

Product Features:

✤Applicable for low flow measurement like lab experiments

✤Providing accurate readings for gaseous CO2

✤Minimal maintenance for its simple structure -- no moving parts

✤Compact design and high efficiency

By understanding the challenges of CO₂ measurement, selecting the appropriate mass flow meter, and leveraging the unique advantages of technologies like Coriolis and thermal flow meters, industries can optimize their processes, reduce costs, and ensure compliance with environmental standards. Whether you're dealing with gaseous CO₂ in emissions monitoring or liquid CO₂ in industrial cooling, the right mass flow meter is an indispensable tool for success.

Post time: Nov-26-2024