Precision is the cornerstone of excellence in the brewing industry. Pinpoint accuracy of alcohol concentration meter makes a solid foundation for both small-batch artisanal whiskey and high-volume production. Traditional methods of alcohol concentration determination are proven being cumbersome and time-consuming, compared with modern automation sensors and technologies.

Challenges of Traditional Alcohol Concentration Determination

Traditional alcohol concentration measurement utilizing a pycnometer or alcoholometer is the mainstream in concentration determination. Nevertheless, shortcomings of those traditional measurements are exposed gradually over the last decades in practical applications.

The classic pycnometer requires a complex and meticulous procedure like sample pretreatment, high-precision sealing and temperature control. Minor deviations in concentration or density are able to incur incomplete alcohol evaporation or over-distillation. The distillate is diluted to its previous or original volume with water and density measurement is proceeded at 20 °C in typical, in which even a ±0.1 °C deviation make a big difference in concentration and density measurement.

The alcoholometer measures alcohol concentration from the immersion depth on the basis of Archimedes principle. Readings of concentration varies significantly for thermal expansion and contraction at different temperatures. Therefore, precision concentration readings derive from a stable environment, involving many factors like temperature, pressure and the like.

Measuring Points in Brewing Processes

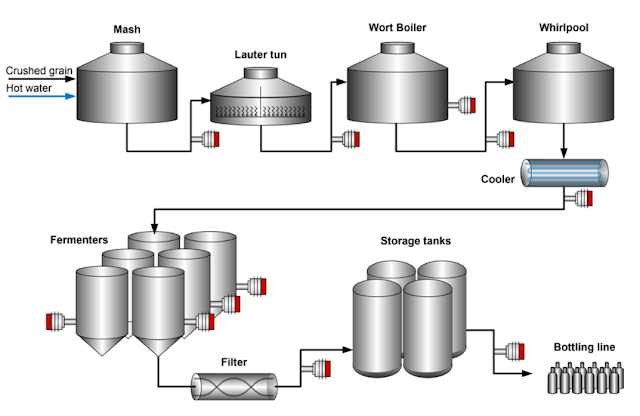

The alcohol density meter allows end-users to integrate the inline density meter or inline concentration meter to improve precise concentration control in brewing processes. Moreover, it is able to offer real-time monitoring of density changes in the fermentation stage, in which conversion from sugar to alcohol is the critical process in wine or spirit making.

The density meter for alcohol also works in real-time concentration monitoring of distillate after exiting the condenser. It's often used to measure alcohol concentration at a standard temperature -- 20 °C. When the alcohol concentration reaches the desired range for premium spirits, the system automatically controls the flow, significantly improving the yield of high-quality products.

Besides, alcohol content is able to be monitored in the long-lasting aging phase, in which alcohol merges with flavor compounds. Online density meters continuously monitor the alcohol content, ensuring stability despite environmental fluctuations. If temperature changes risk causing alcohol evaporation or altering the liquid, the system promptly alerts brewers to adjust aging conditions. This guarantees that the final product, after years of maturation, delivers a rich taste and unique aroma.

The inline density meter alcohol monitors each minutes' density by correlating vibration frequency, minimizing risks of potential manual errors. Outstanding repeatability with deviations as low as ±0.0001 g/cm³ for repeated measurements of the same sample. Durable and hygienic material -- 316L stainless steel is safe enough to contact with liquids even under stringent food safety standards.

The concentration meter alcohol requires only minimal maintenance for simple structure in mechanical design, reducing operational downtime and frequent disassembling and cleaning. Integrating the digital alcohol concentration meter means a forward-looking step to precise automation processes for optimized production. Please contact with our engineers directly if you are confused with any technical problems. Request for quotation now!

Post time: Jan-08-2025