A flow meter is a pivotal measuring device in many commercial and industrial fields. Versatile applications like monitoring water leakage and wastewater treatment processing adopt such flow meters for more precise controlling and efficient productivity, especially processes containing liquids, gases or vapour.

Operators fail to control the throughput in case they are unable to monitor fluid flow. Flow meters provided by the Lonnmeter manufacturer perform effective in improving plant safety, efficiency and profitability via accurate and reliable flow measurement.

What is a Flow Meter?

A flow meter, aka a flow sensor, is a professional instrument in measuring mass or volumetric flow of fluids, gases and even vapours during a given period of time. The total amount of matter gone through could also be measured.

Two types of flow meters are available options for all kinds of plants. An in-line flow meter features a flow line integrated in a process line, in which a built-in flow conditioner adjust the process liquid, gas and vapour to reach specific targets. The installation point of a clamp-on flow meter is flexible without disrupting production. Both of them allow operators applying in versatile industries, substances and pipe thicknesses without process shutdown.

How Does a Flow Meter Work?

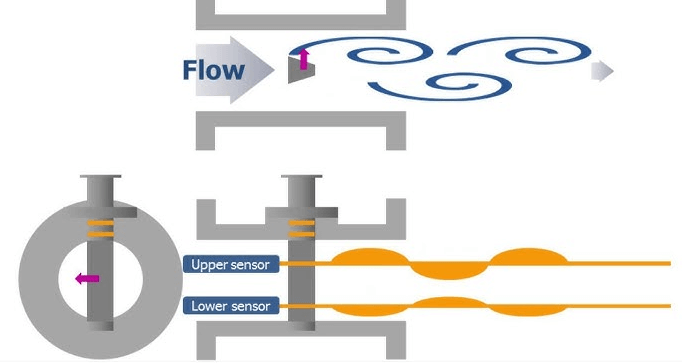

All flow meters applied in process line reach the same target -- measuring and controlling volume and mass of liquids, gases and vapours passing through fixtures. Nevertheless, they do not work in the same way for variations upon type of flow meters.A vortex flow meter is a kind of the frequency meter basically for the measured frequency generated by a "bluff body" or "shedder bar". In other words, the flow rate and velocity is measured accurately based on the von Kármán effect. Alternating vortices are formed behind a resisting fluid as the fluid flows through it. Frequency of alternating vortices is proportional to the velocity of the fluid.

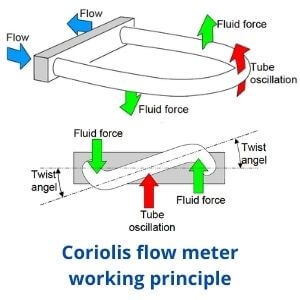

For instance, the Coriolis flow meter operates based on principles of motion mechanics. It is forced to accelerate the fluid forward as passing through a vibrating tube to the point of peak-amplitude vibration. On the contrary, the fluid is decelerated from the point of peak amplitude as it exits the tube.

The essence is a twisting reaction of the fixture like a flow tube under flowing conditions when the fluid sending through every vibration cycle. An actuator stimulates a small tube to vibrate at the natural resonant frequency. Two sensors along the tube capture the deflection of the vibrating tube in time. The mass of fluid produces additional twists to the tube for the sake of fluid's inertia. The difference of deflections between an empty and a tube with fluid through is a direct measure of the mass flow. Such a phase shift is proportional to the mass flow rate.

Market Applications of Flow Meters?

Those flow meters are critical in many fields like metallurgy, electric power, coal, chemical industry, petroleum, transportation, construction, textile, food, medicine, agriculture, environmental protection. They weigh in the national economy.

Lonnmeter offers flow meters across various industries to ensure accuracy and efficiency, from precision demands of aerospace and aviation to intricate processes of the chemical and petrochemical sector. Advanced and cutting-edge flow meters are also used in laboratories for precise measurement in research and experimentation. Moreover, they are often used to optimizing production processes for pursuing to higher operational efficiency.

Energy sector is another paragon of flow meters in practical application, providing reliable and accurate data for monitoring and managing of fluid motions in complex systems. They are also appeared in pharmaceutical and food industry for the purpose of precise controlling.

For example, flow of oil and gas should be measured in precise in spite of the purity when flowing through long pipelines. With the assistance of flow meters, how much gas and oil being processed could be shown and recorded.

Rapid urbanization, climate change and increasing demands are all challenges facing the water industry. In viewing of such backgrounds, they are indispensable instruments to water treatment. Flow meters feature mechanisms to prevent clogs in complex systems, even thicker wastewater like sludge.

Food and beverage industry take the advantages of flow meters to improve efficiency and save raw materials in response to fierce competition and rising energy costs. In addition, such meters work in quality improvement, which benefits from precise controlling.

Get Professional Assistance Here

Lonnmeter is a trusted leader in flow measurement solutions, specializing in gas, steam, and liquid applications. Our extensive range of in-line and clamp-on flow meters is designed to optimize your processes, improve efficiency, and meet both environmental and performance objectives.

Whether you're aiming to reduce waste, increase accuracy, or streamline operations, our expert team is ready to assist. Contact us today to discover how our flow meter solutions can help meet your unique business needs and drive success in your industry.

Post time: Oct-17-2024