Brine Concentration Measurement

Sodium Chloride (NaCl) concentration measurement is a fundamental and crucial sector in chemical and mining industry, in which real-time continuous concentration monitoring matters to fulfill specific requirements.

What is Brine?

Brine or briny water means a high-concentration solution of salt like NaCl or calcium chloride, a liquid mineral resource with a salt content over 5%. It contains various ions like including potassium (K⁺), sodium (Na⁺), calcium (Ca²⁺), magnesium (Mg²⁺), and chloride (Cl⁻). In general, brine density varies in different origins and extraction depth. It could be categorized into shallow and deep brine according to burial depth. The former could be found near the surface, while the latter exists in an enclosed environmental. Moreover, deep brine often found in the vicinity of oil, gas, and rock salt deposits.

Factors Affecting Brine Density

Temperatures, impurities, instrument errors and wrong measuring methods are all factors to influence density or concentration output. Let's dive into those factors one by one:

Density of briny water follows the Expansion and Contraction principle. In other words, molecules move farther apart as temperature increases while move closer as temperature decreases. The density-temperature relationship is non-simple linear. For instance, temperature coefficient for NaCl is influenced by its concentration. There are significant deviations in density or concentration measurement without temperature compensation.

Impurities like salts, solids (calcium chloride or magnesium chloride) and sands are able to alter real-time density. Other salts skew the overall density. Without adequate pretreatment, such as filtration, density measurements can be unstable or incorrect. The varying impurity content in different brine sources adds to the complexity.

Instrument errors may deviate density or concentration, too. Inline brine density meters vary in precision levels. Low-precision devices are inadequate for applications requiring one ten-thousandth accuracy, like fine chemical production. Moreover, triggering factors like calibration errors, damage, and wear can lead to inaccurate readings. Sensor drift may be occurred for the sake of corrosion and wear of vibrating components.

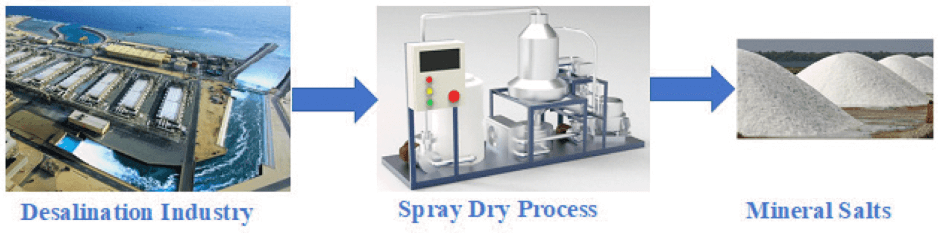

Related Industrail Applications

Recommended Inline Density Meters

Differential Pressure Density Meter

Based on gravity and buoyancy balance, it measures the pressure generated by a liquid column at a fixed height, which is proportional to the liquid’s density.

Characteristics:

1. Applicable to both static and flowing liquids;

2. Continuous density & temperature measurement without process interruption;

3. Dual parameter display for temperature and density, simplifying standardized density conversions;

4. Multiple material options for contact components to accommodate different brine media.

Fork Type Density Meter

It measures frequency changes as the tuning fork vibrates within the measured liquid, correlating directly to liquid density.

Characteristics:

1. Easy to install and maintain with plug-and-play functionality;

2. Capable of measuring density in liquids containing bubbles or fixed mixed media.

Post time: Jan-15-2025