Sodium Hydroxide (NaOH), aka caustic soda or lye, is a crucial component in most industrial processes, especially inevitable in production of diluents, plastics, bread, textiles, inks, pharmaceuticals and pigments. Precise concentration of NaOH are an essential factors influencing product quality.

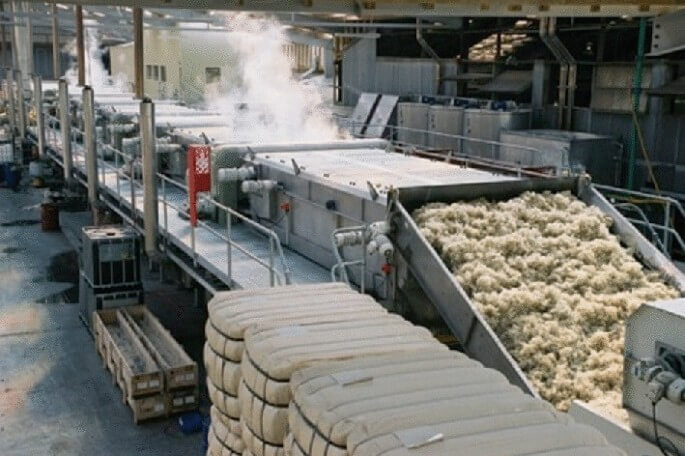

NaOH concentration weighs in pretreatment of natural fibers (like cotton and wool) and synthetic fibers in the textile and dyeing industry. Impurities like grease, wax and starch are intended to eliminate in the pretreatment. Higher NaOH concentration may cause irreversible damage to fibers while lower NaOH concentration fails to reach expected effects regarding impurity elimination. Therefore, real-time NaOH concentration monitoring is a prerequisite of smooth dyeing and finishing processes to improve fabric dye uniformity and color vibrancy.

Drawbacks of Conventional Titration

Titration is the most commonly used method to measure the concentration of NaOH solution, also a time-consuming and labor-intensive method when compared with intelligent inline density meter for liquids. Moreover, titration could not detect real-time changes in concentration and introduces manual errors in case operation factors change.

Furthermore, titration is applicable to batch analysis rather than compatible with automation batching system in real time. At the same time, it is not suitable for high-frequency concentration measurements. Operators are exposed to environments featuring volatile or hazardous substances in case there are corrosive or volatile additions in the whole production line.

Improvements of Precise Batching in Automation Processes

The in-line liquid density meter, aka a non-nuclear density meter, integrated into automating processes of textile and dyeing facilities takes effects on following technical processes like desizing, sourcing, mercerization, dyeing, printing, etc.

Desizing agents are dissolved into water to eliminate sizing materials from fabrics, such as NaOH solutions at a certain concentration designed for specific fabrics. The automatic density meter ensures the desizing solution staying within optimal range for thorough elimination. It prevents occurring of technical problems like uneven dyeing and insufficient desizing, reducing costs of rework and improving dyeing and printing efficiency.

Caustic soda and other chemicals are used to remove impurities from fabrics in sourcing. Precise batching of chemicals could be adjusted automatically according to real-time density or concentration data. Thereby, fabric whiteness, permeability and other indicators are enhanced greatly. Meanwhile, it's similar to mercerization process.

The dye solution density could be monitored by the digital density meter for liquids during dye preparation. Enables precise control of dye concentration, ensuring uniform and accurate dyeing while avoiding color variations caused by fluctuations in dye concentration. The liquid concentration meter improves the first-pass yield of dyeing, reduces defects, and minimizes waste. It's applicable to density monitoring of color pastes in color paste preparation for printing.

Please contact the leading manufacturer Lonnmeter instantly to figure out whether the inline density meter is applicable to your production line or not. Request a free quote now!

Post time: Jan-10-2025