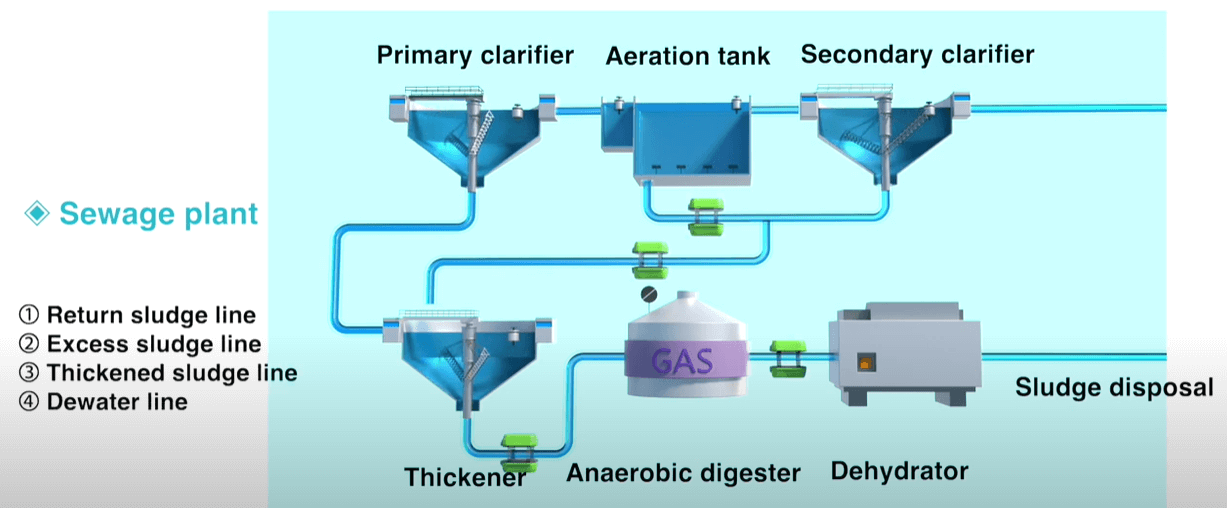

Lonnmeter, a sludge density meter manufacturer, design and produce an innovative sludge density meter. The inline density meter for sludge is installed at many industrial applications as well as municipal water and wastewater plants. For sewage plant, the sludge concentration meter is applied at raw, return, excess, thickened, and dewatering process.

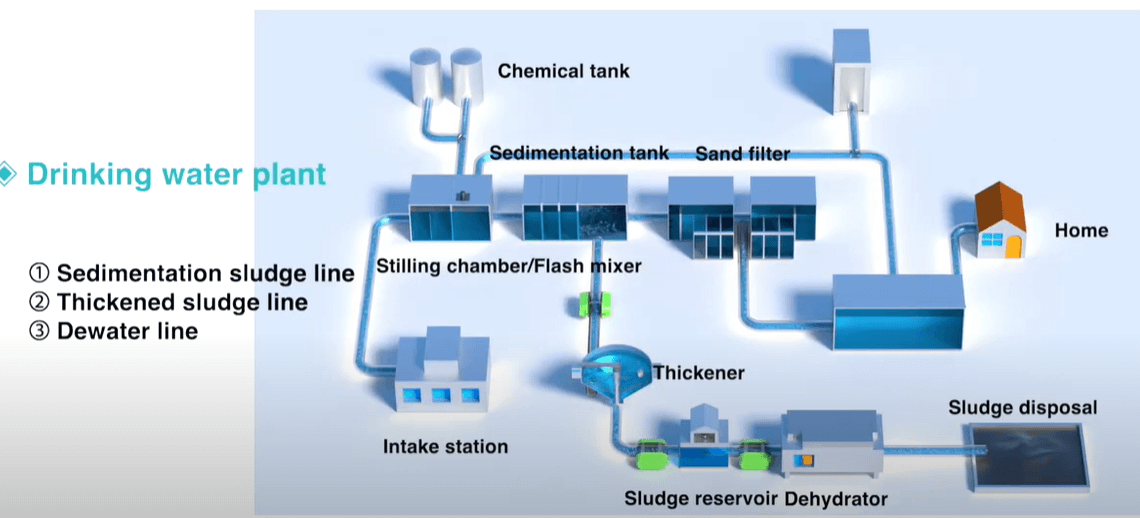

The density measurement tool is operated at sedimentation and thickening process to monitor the density during sludge discharge in water treatment plant, too. It could be used in following processes of in drinking water. By monitoring the density variation at the dewatering process in real time, the density measurement device saves the amounts of chemical usage and extends decanter's life expectancy drastically as it automates screws rotation speed.

Outcomes of Inaccurate Density Measurement

Inaccurate density measurement of sludge may hinder in-time or inaccurate adjustments, turning the final effluent failing to meet discharge standards and incurring municipal fine further. The substandard treatment may leave pollutants like suspended solids, organic matter and heavy metals untreated, having harmful impacts on surrounding environment and healthy of nearby residents. Besides, it is possible to affect dosage distribution and result in chemical wastage, then the cost of treatment will increase too.

Furthermore, inaccuracy of density data increases risks of potential equipment wear and tear, shortening lifespan of related lines. Then subsequent maintenance and replacement costs are towering over cost in purchasing a density measurement instrument.

Strengths of Density Measuring Instrument in Automation Lines

The density meter in pipeline enables the monitoring of momentary density changes shook off frequent manual sampling and long interruptions in the process flow. The accuracy of real-time density monitoring is elevated to a higher level, and then operators are able to make firm decision based on reliable data for precision control. The density meter instrument is also adaptable to complex conditions. For example, a fork density meter is able to measure density of mixtures containing solids smaller than 10 um.

The continuous flow density meter features a compact design and is easy to install. They can be directly mounted on pipelines or tanks without requiring large-scale modifications to the wastewater treatment system. Additionally, they do not require standard reference sources, laboratory calibration, or process interruptions during calibration.

Precise density monitoring in real time is critical for reducing costs and maintain process quality in chemical dosing, sludge dewatering and sustainable operations.

Take the first step toward smarter sludge management today. Request a free quote now and explore how our cutting-edge density measurement solutions can transform your operations. Let us help you build a more efficient, cost-effective, and environmentally compliant treatment system.

Post time: Jan-08-2025