Accurate flow rate measurement is critical in efficient energy maintaining and industrial precessing and like chemical plants. Select an appropriate method is paramount according to fluid type, system requirements, and even application specifics. Characteristics of fluids vary in the viscosity, density, temperature, pH value and corrosive power. Moreover, system conditions like pressure, flow regime and applied environment should be accounted for.

What is Flow Rate?

Flow rate refers to the quantity of fluid sending through a point per unit time. It is measured in units such as liters per second or gallons per minute in typical. It's a significant parameter in hydraulic engineering and medical science. Engineers are able to gain insights to fluid regime, especially contributing to optimizing industrial processing and making informed decisions.

Factors Influencing Flow Rate

Understanding factors affecting flow rate is the prerequisite of choose the best scenario of flow rate measurement. The fluid type, property, flow regime, temperature, pressure, pipe size, configuration and installation conditions are all factors to influence the flow rate.

Identify the Type of Fluid

It's crucial to identify which medium you are dealing with. The specific flow measurement technology should be adopted for distinct of each fluid. For instances, gases could be compressed but the liquids do not; density of steam is variable. Higher viscosity fluids like oil propagate through pipelines differently than lower viscosity fluids like water. It's necessary for owners and engineers of various plants to pick appropriate technologies for accurate measurement and precise controlling.

How to Measure Flow Rate?

Volumetric or Mass Flow Meters

Making a choice between volumetric or mass flow measurement is an essential step before optimizing the accuracy of fluid systems. Volumetric flow meters are ideal for fluids of density staying in a stable level, especially most of the liquids and gases in a processing system. Mass flow measurement is necessary in case the density changes with temperature and pressure. Just in view of this reason, mass flow meters are applied to capture the total amount of material passing through a point per unit time.

Select the Appropriate Flow Meter

Volumetric Flow Meters

Ultrasonic Flow Meter

Magnetic Flow Meter

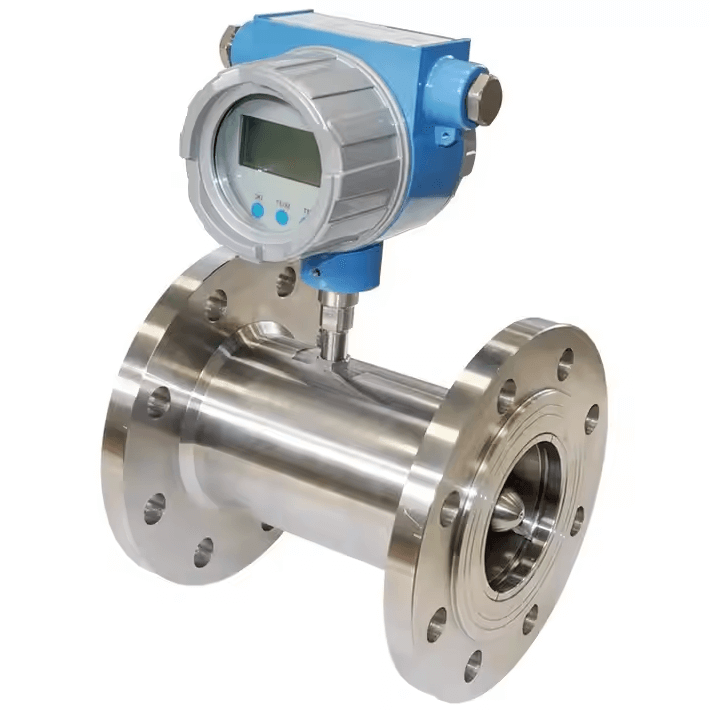

Turbine Flow Meter

Mass Flow Meters

Click here and view more info on types of flow meters.

Measure the Reynolds Number (If Necessary)

Measure the Reynolds number to predict flow regime based on fluid velocity, density, viscosity and pipe diameter, either laminar or turbulent. The fluid could be considered as laminar when the Reynolds number below 2,000 approximately. In other words, fluid is turbulent when the Reynolds number above 4,000. Check the flow regime through Reynolds numbers for significance of performance and accuracy of flow meters.

Flow Meter Installation

Installing the flow meter in a straight section to devoid bends, valves and other disruption is the best solution for optimal performances, at which fluid flow remains steady and uniform. In addition to above factors, alignment is another reason affecting accuracy of meters for flow disturbances triggered by any kind of misalignments. Operational errors and effectiveness could be improved as much as possible if all those details are accounted for in installation.

Execute Necessary Calibration before Consistent Measurement

Calibration is essential to guarantee the accuracy of your flow meter, especially in industrial applications where precision is paramount. Conducting calibration involves comparing the meter’s output with a known standard and adjusting as needed to ensure readings are within acceptable tolerance levels. Regular calibration not only maintains the meter’s accuracy but also extends its operational life, preventing costly errors or inefficiencies in process control.

Post time: Oct-16-2024