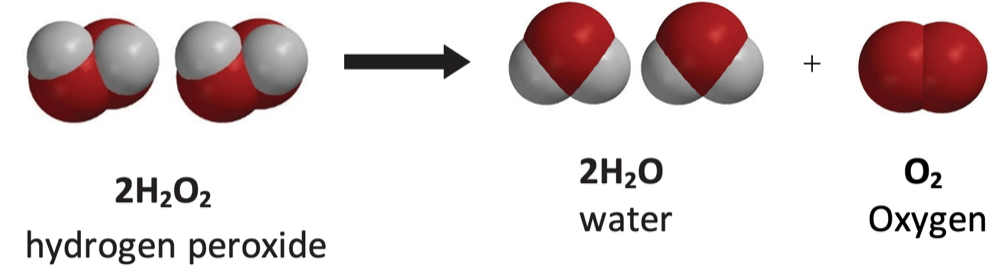

Propylene oxide is taken as an intermediate in manufacturing of polyurethane, antifreeze and other industrial chemicals. A pipeline density meter is integrated into the production line of propylene oxide manufacturing facility -- Propylene Oxide Plant for precise control over chemical reaction, in which one important reactant hydrogen peroxide (H₂O₂) reacts with propylene in the presence of a catalyst to form propylene oxide.

Reaction rate, product quality and overall efficiency all could be adjusted through a hydrogen peroxide concentration meter at various stages of production. The main reaction rest on epoxidation reaction, where propylene reacts with hydrogen peroxide (H₂O₂) in the presence of a catalyst (usually a tungstate or molybdate-based catalyst) to form propylene oxide (C₃H₆O) and water (H₂O).

Measuring Points of in the Production of Propylene Oxide

Critical measuring points include raw material inlet, reaction vessel, separation and recovery phase, etc. Hydrogen peroxide feed inlet is a necessary point to ensure required specifications. In general, hydrogen peroxide is stored in concentrated form, and it needs to be diluted prior to further processing or reaction with other chemicals.

Then come to the reaction vessel or reactor. This is another measuring point of hydrogen peroxide concentration measurement so that the reaction is progressing as expected. An inline process density meter or other sensor is able to installed at the reactor outlet to monitor real-time concentration of hydrogen peroxide as it reacts with propylene. The intelligent density meter online enables dynamic adjustments of hydrogen peroxide possible for its continuous monitoring. In case the concentration falls too quickly or the reaction doesn't go forward as expected, it's necessary to adjustment the flow of hydrogen peroxide into the reactor.

Post-reaction involves the separation and purification of propylene oxide and by-products, such as water and unreacted hydrogen peroxide. For example, high-level hydrogen peroxide pose risks to environmental sustainability and human's safety. Proper concentration measurement makes quantification and sustainable processing possible to comply with laws and regulations.

Intelligent measuring systems at crucial points in the process helps a lot in production optimization. Employing advanced technologies like online densitometers, spectrophotometers, and titration methods allows for real-time monitoring, accurate concentration measurements, and better process control, ultimately leading to higher yields and safer operations.

Please contact Lonnmeter engineers for more consultation about the inline hydrogen peroxide concentration meter to figure out whether it could be applied to your production line or plants. Request a free quote now and get the price of the density meter.

Post time: Jan-17-2025