In 1938, Nestle adopted the advanced spray drying for instant coffee manufacturing, allowing powder of instant coffee to dissolve quickly in hot water. In addition, small volume and size makes it easier in storage. So it has developed rapidly in the mass market. Currently famous instant coffee brands include Nestle, Maxwell, UCC, etc.

Instant coffee production process

Instant coffee is a coffee solid beverage processed by coffee bean roasting and crushing, soluble matter extraction with water, and then drying with hot air or freeze drying. It’s easy being dissolved into water and turn back to liquid coffee with original taste and flavor. The production process is as follows: screening of coffee beans, impurity removal, roasting, grinding, extraction, concentration, drying, packaging.

II. Key Points of Instant Coffee Production Process

(I) Pre-Treatment of Raw Coffee Beans

First, the raw materials should be carefully selected. Fresh coffee beans are bright, round and uniformed in size, excluding moldy, fermented, black, worm-eaten, extremely broken and other inferior beans, as well as various impurities such as seed shells, soil blocks, wood blocks, stones, and metals. In order to ensure quality, separation can be carried out by means of vibrating screens, wind pressure or vacuum conveying.

(II) Roasting

Roasting is the decisive process for the formation of the flavor and quality of instant coffee. Commercial processes of coffee beans adopts half hot-air direct fire roaster or hot air roaster with roasting chambers in the form of rotary drum in general. Roasting temperature and roasting time are key decisive factors.

The length of roasting time varies not only due to the variety and type of coffee, but also depends on the degree of roasting required for the final product. Short roasting time indicates coffee beans are soft with strong acidity, weak bitterness and easy extraction after grinding. On the contrary, long roasting time indicates coffee beans are crispy with weak acidity, strong bitterness and low-efficiency in extraction for much fine powder.

Insufficient roasting will result in poor aroma, poor color of the finished product and low extraction rate; excessive roasting will result in more oil precipitation, which will hinder extraction and affect the spray drying operation. Therefore, good roasting conditions must be determined by the product color, aroma, yield, economic efficiency and production equipment design conditions.

When the coffee beans reach the required roasting degree, turn off the fire, stop heating, and cool the coffee beans immediately. Because even if the heating is stopped, the heat inside the coffee beans will continue to be roasted for a period of time, so after the coffee beans are poured out of the drum roasting chamber, the exhaust fan should be turned on to cool them down to stop the temperature from rising. In industry, a certain amount of cold water is sprayed into the roasting chamber to cool it down, and then the roasted coffee beans are discharged from the roasting chamber for cooling.

(III) Static Storage

It is best to store the roasted coffee beans for one day to allow the carbon dioxide and other gases to further evaporate and release, while also fully absorbing the moisture in the air to soften the beans, which is conducive to extraction. The size of the grinding particle size is related to the extraction equipment used. Fine particles are conducive to high-efficiency extraction but hinder subsequent filtration while coarse particles are difficult for extraction but easier for filtration. Generally, the average diameter of the ground coffee particles is about 1.5 mm.

(IV) Extraction

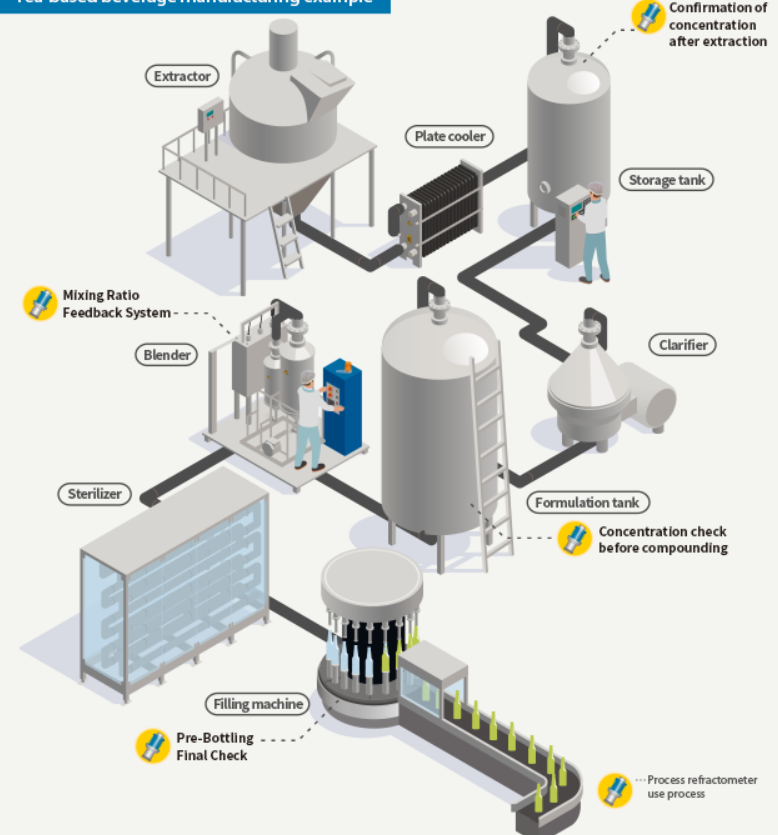

Extraction is the most complex central part of the instant coffee production process. The equipment generally used for extraction is called an extractor, which consists of 6 to 8 extraction tanks connected to each other by pipes and can be alternately formed into an operating unit.

(V) Liquid-Solid Separation

The extracted coffee liquid will have a lot of solids left. This requires liquid-solid separation of the coffee liquid before it is transported to the next process. A butterfly separator can achieve the required separation effect in general.

(VI) Concentration

Concentration is categorized into vacuum concentration, centrifugal concentration and frozen concentration in general. In order to improve drying efficiency, reduce equipment investment and energy consumption, the solid concentration is condensed to reach more than 35%. Vacuum concentration lowers the boiling point of water to about 60 degrees in vacuum pressure over 0.08Mpa. So that the liquid is concentrated faster. An inline coffee slurry concentration meter helps end-uses out of repeated and bothering concentration determination by its high-accuracy monitoring in real time. The concentration of the concentrate generally does not exceed 60% (refractometer). Since the temperature of the concentrated liquid coming out of the evaporation tower is higher than room temperature, it must be cooled before being sent to the storage tank to reduce loss.

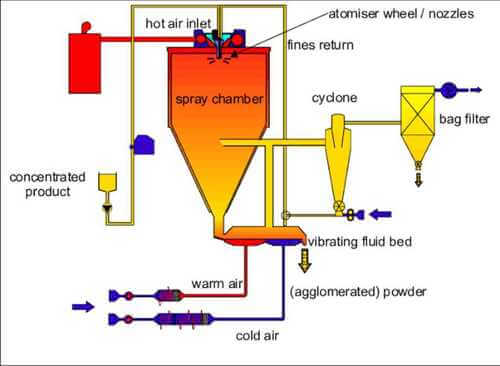

(VII) Spray Drying

The concentrated liquid is directly transported to the top of the spray drying tower through a pressure pump, sprayed into mist by a pressure spray gun, and dried into powder under heat and wind airflow at about 250°C. Vacuum drying or freeze drying technology can also be used for drying. Freeze drying technology is to freeze the coffee concentrate at low temperature, and the water in it is frozen into fine ice crystal particles, and then heated and sublimated under high vacuum conditions to achieve the purpose of low-temperature drying. After the concentrate is processed, the necessary addition treatment can be carried out on the concentrate, and it can also be developed into a liquid beverage.

Click here for more solutions of inline concentration monitoring. Or you can contact Lonnmeter directly with your specific requirements.

Post time: Feb-10-2025