Bulk Density of Paper Pulp

Lonnmeter has designed and developed measuring devices for bulk density of paper pulp, black liquor and green liquor. It's possible to determine the density of dissolved or non-dissolved components through a single density meter installed in line. We offer solutions to the density and concentration measurement for applications like black liquors, green liquors paper pulps. In addition, pulp density meters are able to measure the density of lime mud in case of without large-sized particles and loads of bubbles.

Why Need Continuous Density Measurement?

Uneven pulp in paper making brings potential risks on unstable quality of final products and increase cost in paper making. Paper pulp consists of a suspension of fiber in water evenly. The non-uniformity in density influences the whole paper making process.

Variable consistency of the pulp leaves its viscosity changes with the rate of shear, adding another layer of complexity to continuous density measurement. Irregularities grow further for the reason of entrapped air, which embodies as bubbles in the mixture, causing false readings and undermining precision.

Traditional methods employed for density measurement often come across in accuracies in the face of changing operations. For instance, gravimetric methods are not appropriate to continuous monitoring for the sake of labor-intensive nature and susceptibility to sampling errors.

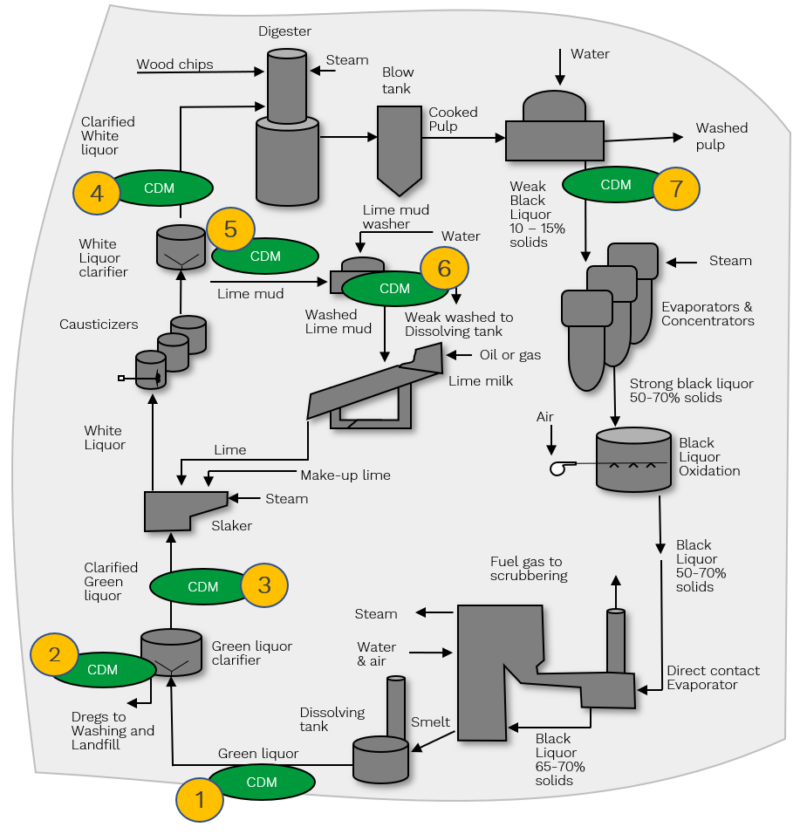

Measuring Points in Paper Pulp Process

Get clues from the above diagram in paper making, there are seven points to install a chemical density meter for process optimization in total. They work in following aspects:

1. Dissolving process of black liquor in water;

2. Green liquor density or concentration monitoring;

3. White liquor density or concentration monitoring;

4. Lime slurry density or concentration monitoring;

5. Weak black liquor density or concentration.

The kraft process converts wood into wood pulp, in which black liquor or spent liquor is formed with wood pulp. Then the black liquor is processed until green liquor is formed. Furthermore, it could be turned to white liquor by adding lime milk for recovery. Therefore, density or concentration control in above measuring points is critical for quality and cost control.

Recommended Density Meter

Lonnmeter pulp density meter is an ideal option for continuous density monitoring in precision control, offering accurate readings to operators in real-time. Its precision reading can reach ±0.002g/cm³, and the measurement scope falls in 0-2 g/cm³. The output is delivered in 4-20 mA signal. So that end-users could adjust processing parameters instantly for more stable quality and consistency, such as the addition of paper pulp, water content and rate of agitation.

In addition, real-time monitoring of paper pulp is benefit to discover abnormalities in processing, like variable consistency, non-uniformity of paper pulp and even equipment breakdown. Then further measures could be taken promptly to avoid production loss and useless byproducts.

Contact our engineer for more details about the pulp density meter, and you can get processional suggestions about selecting an appropriate inline density meter. Request a free quote now!

Post time: Jan-06-2025