-

Dense Liquid Density Measurement in Coal Preparation

The dense liquid is a high-density liquid used to separate the desired ore from rocks and gangue minerals. It exhibits good chemical stability, resisting decomposition, oxidation, and other chemical reactions, to maintain its density and separation performance in general...Read more -

Anhydrous Sodium Sulfate (Na2SO4) Density Measurement in Production of Sodium Silicate

Anhydrous Sodium Sulfate (Na2SO4) is the primary raw material in production of sodium silicate, and the sodium ions in sodium sulfate are essential for forming sodium sulfate. Sodium is introduced into the molecular structure of sodium silicate when sodium sulfate reacts...Read more -

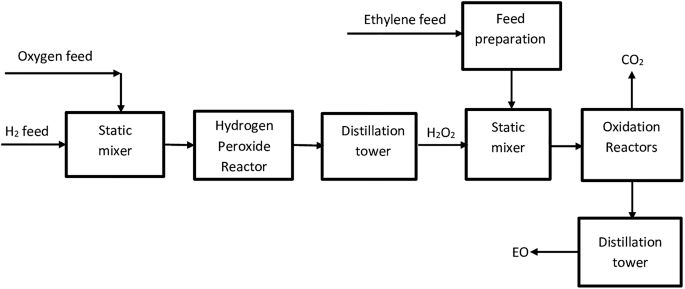

How to Measure Hydrogen Peroxide Concentration in Mass Production of Propylene Oxide?

Propylene oxide is taken as an intermediate in manufacturing of polyurethane, antifreeze and other industrial chemicals. A pipeline density meter is integrated into the production line of propylene oxide manufacturing facility -- Propylene Oxide Plant for precise control...Read more -

Tool Measuring Water vs Oil Concentration in Cutting Fluid

Accurate and stable concentration of cutting fluids is beneficial to extensive life and quality of tools produced from metalworking. And it turns unexpected breakdowns a thing of the past. The secret to realize the vision often rests on an overlooked factor -- precise co...Read more -

Revolutionary Technologies Transforms Lithium Extraction

Stanford University researchers make great breakthroughs in developing new technologies for extracting lithium from briny water. The more efficient and eco-friendly method addresses lithium concentration problems in traditional extraction and processing. The technology e...Read more -

How to Determine Brine Concentration in Brine Mining?

Brine Concentration Measurement Sodium Chloride (NaCl) concentration measurement is a fundamental and crucial sector in chemical and mining industry, in which real-time continuous concentration monitoring matters to fulfill specific requirements. What is Brine? Brine or ...Read more -

How to Determine Concentration of NaOH Before Pre-processing of Fibres?

Sodium Hydroxide (NaOH), aka caustic soda or lye, is a crucial component in most industrial processes, especially inevitable in production of diluents, plastics, bread, textiles, inks, pharmaceuticals and pigments. Precise concentration of NaOH are an essential factors i...Read more -

How to Measure Ethylene Glycol Concentration in Antifreeze Production?

Ethylene glycol concentration measurement is critical for quality control in antifreeze production, also one of the primary raw material. Ethylene glycol is the main component of antifreeze. In general, the concentration of ethylene glycol in antifreeze varies in differe...Read more -

How to Measure Methanol Content?

Continuous methanol concentration measurement is critical in production of direct methanol fuel cell (DMFC), especially in improvement of power generation efficiency and battery life extending. The power generation efficiency is determined by the oxidation reaction rate ...Read more -

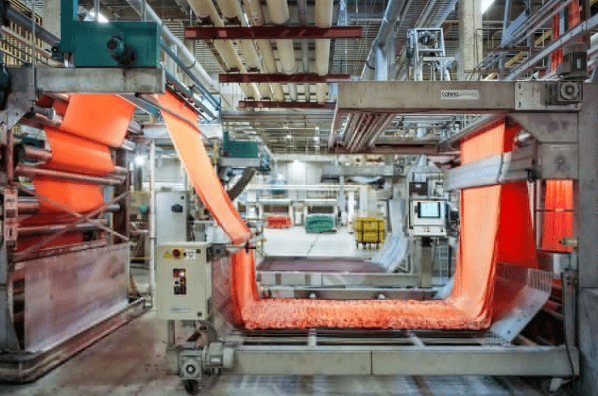

Automated Density Measurement Reduces Costs by 25% in Dyeing & Printing Factory

Lonnmeter is one of the competitive manufacturer of inline density meter. The printing paste density meter enables momentary density monitoring breaking away from frequent manual sampling and interruptions in the process flow. It works in additive addition, printing past...Read more -

How to Measure Density of Sludge in Water Treatment Plant?

Lonnmeter, a sludge density meter manufacturer, design and produce an innovative sludge density meter. The inline density meter for sludge is installed at many industrial applications as well as municipal water and wastewater plants. For sewage plant, the sludge concentr...Read more -

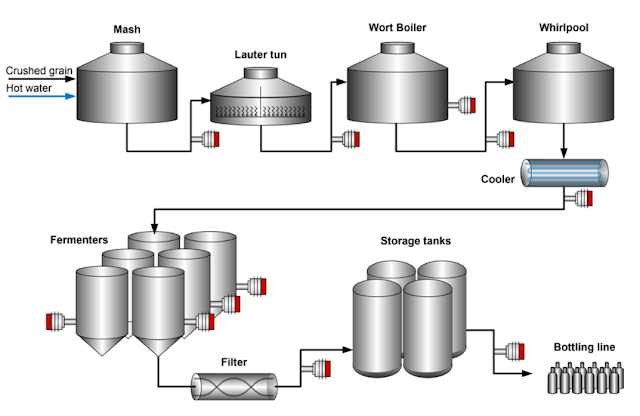

How Does a Density Meter Determine Alcohol Concentration

Precision is the cornerstone of excellence in the brewing industry. Pinpoint accuracy of alcohol concentration meter makes a solid foundation for both small-batch artisanal whiskey and high-volume production. Traditional methods of alcohol concentration determination are...Read more

Make measurement intelligence more accurate!