In the manufacturing of printed circuit boards (PCBs), the surface of fiber-reinforced plastics should be covered with copper coatings. Then conductor tracks are etched onto the flat copper layer, and various components are soldered onto the board in subsequent.

PCB cleaning aims at removing impurities like films or particle residues from flux, resin, or solder paste. These impurities can cause electrical faults and corrosion in the circuit board or its components. In general, single-chamber, multi-chamber, and continuous-flow cleaning systems are used for PCB cleaning.

The PCB cleaning improves both lifespan and reliability of products. Electrical parameters of electronic components are able to improve through purification. Therefore, consistent control regarding cleaning baths are critical in the whole cleaning.

PCB cleaning involves one or more water-based rinsing steps, which is often carried out in spray cleaning systems. In consequence, the volume and density of cleaning liquids sprayed out from nozzles should be measured accurately.

Water-based and anhydrous (non-water) cleaners are commonly used. Water-based cleaners are preferred for no flash point and contain low levels of volatile organic compounds (VOCs).

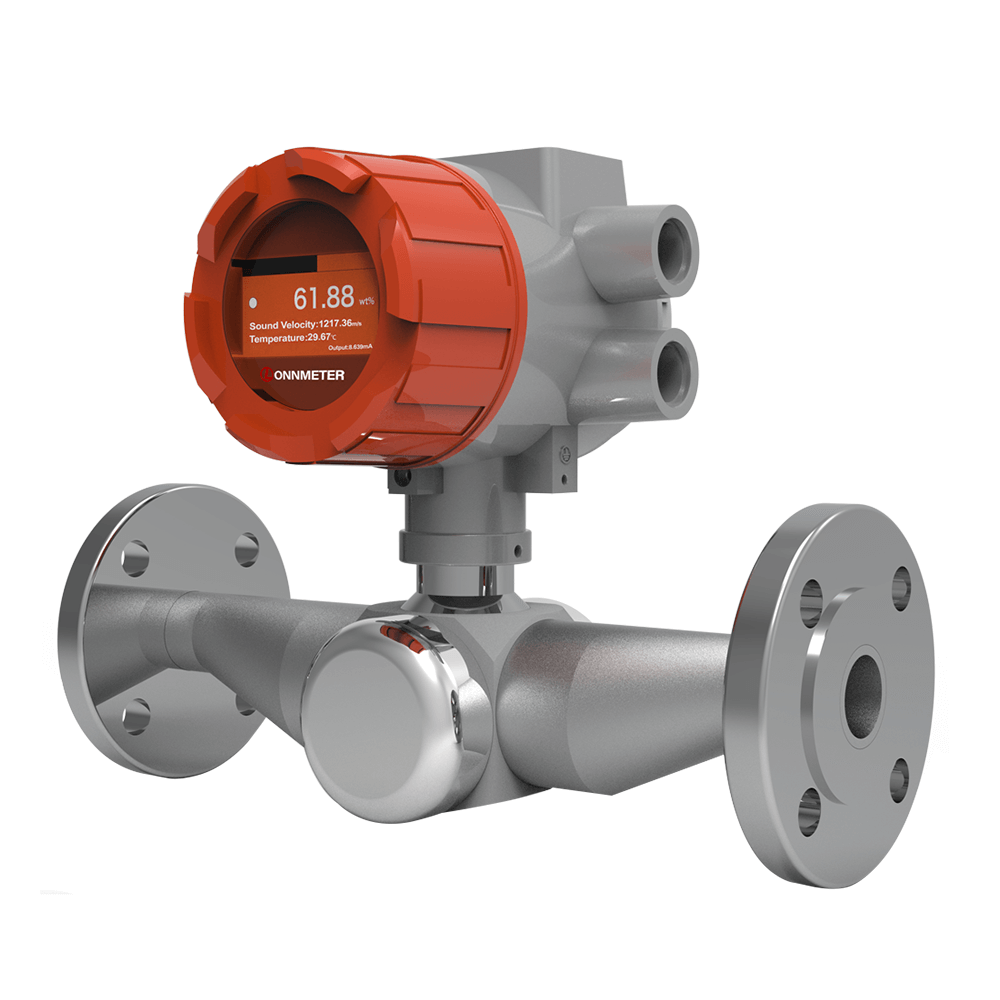

Years of experience have shown that Lonnmeter concentration meters are highly reliable for controlling bath liquid concentration, ensuring the correct cleaning chemical levels. These meters provide real-time data and permanent data logging, which are crucial for maintaining high product quality and avoiding defects.

Lonnmeter inline chemical concentration meters are used to monitor the concentration of bath cleaning liquids in real-time. The output readings are displayed online and can be directly transferred to the process control system. This allows for a quick response to any deviation. For instance, refilling or replacing the bath solution for better cleaning and to avoid quality fluctuations during the cleaning process.

Benefits of Lonnmeter Liquid Concentration Meter:

- Quick Detection of Quality Changes: Real-time monitoring ensures that any changes in the bath can be detected promptly, allowing for quick adjustments.

- Internal Data Storage: The system stores data internally, supporting quality management and ensuring traceability.

- Optimizing Lifespan of Cleaning Containers: Continuous monitoring helps extend the lifespan of a cleaning container by ensuring it’s used efficiently and not replaced prematurely.

- Avoiding Overuse or Early Changes: By providing precise concentration levels, Lonnmeter helps prevent unnecessary replenishment of cleaning agents, saving on material costs.

- Best Cleaning Performance (Process Safety): With accurate concentration monitoring, cleaning performance is maximized while ensuring its safety and effectiveness.

- Cost Savings: By preventing overuse of chemicals or insufficient dosages, Lonnmeter helps minimize material waste.

Lonnmeter density and concentration meters are installed in the circulation loop just after the pump in typical or in the cleaning or rinsing tank directly. The sensor’s electronic components are housed in a durable casing, making them suitable for cleaning process systems that use high-pressure cleaners. In addition, the online concentration meter can be installed in hazardous areas where non-water-based cleaning agents are used.

Measurement Ranges:

- Concentration Range: 20-40 vol%

- Temperature Range: 30-60°C

By accurately measuring the concentration and temperature of cleaning bath container, Lonnmeter helps ensure that the cleaning process remains consistent and efficient, reducing the risk of damage to the PCB and enhancing overall product quality.

Post time: Feb-26-2025