Biogas grows increasingly valuable against the background of depleting fossil fuels. It contains a highly corrosive component hydrogen sulfide (H₂S), which reacts with metal materials like pipelines, valves and combustion equipment. The reaction turns out to be harmful to mechanical strength and equipment lifespan.

Desulfurization is environmental friendly processing in reducing emissions of sulfur dioxides, which is the primary inducement of acid rains and air pollutions. The desulfurization is a necessary measure to meet stringent environmental regulations. Besides, it improves efficiency of combustion for cleaner burning, improving energy output and reducing operational costs meanwhile.

Challenges in Traditional Biogas Desulfurization

Key issues exist in the process of traditional biogas desulfurization like, postponed measurement, manual errors, high labor intensity and safety concerns. Let's dive into the above issues one by one now.

Manual sampling at intervals is the main method to monitor density. Nevertheless, the density of the desulfurization liquid may vary during the time gaps, which causes critical anomalies are missed in sudden acceleration or deceleration of desulfurization reactions. The postponed measuring hinders end-users to find problems and solve them timely.

Manual operations in sampling and transferring leave opportunities for errors. For instance, the desulfurization liquid is prone to react with air or contaminated by impurities, incurring inaccuracy in measurement. Moreover, unreliable readings may be caused by observer angle, bubbles in the liquid or environmental changes.

Labor-intensive manual sampling and measurement contribute to intensive workload and high operational cost, especially in large-scale desulfurization plants with many measurement points. And operators exposed to harmful substances from desulfurization liquids frequently face healthy issues to a certain degree. Furthermore, frequent manual operation in the environment of flammable biogas may incur static electricity and even sparks.

Functions of Liquid Density Meter

In biogas desulfurization processes, online density meters play a critical role by improving efficiency, safety, and environmental compliance. Here are their key applications:

- Monitoring Desulfurization Liquid Concentration

In wet biogas desulfurization, an alkaline solution is used to remove hydrogen sulfide (H₂S) through countercurrent contact. The concentration of the desulfurization liquid correlates with its density, which online density meters can monitor in real time. This enables operators to maintain optimal liquid concentrations, ensuring efficient H₂S removal and process stability. - Optimizing Reaction Conditions

The density of the desulfurization liquid changes as reactants are consumed and products are formed during the chemical reaction. By tracking these density variations, online density meters provide insights into reaction progress and efficiency. Operators can adjust parameters like temperature, pressure, and additive proportions to enhance the desulfurization rate and improve sulfur removal performance. - Controlling Wastewater Treatment

The desulfurization process generates wastewater containing high levels of sulfates and other pollutants. By monitoring the density of this wastewater, online density meters help determine contaminant concentrations, enabling precise adjustments in wastewater treatment strategies to meet environmental standards. - Preventing Equipment Blockages

In processes like atmospheric wet oxidative desulfurization (e.g., using sodium carbonate solutions), inadequate liquid circulation or improper spray density can lead to blockages in desulfurization towers. Online density meters provide early warning by detecting density shifts, helping to prevent issues like fouling or clogging of packed beds. - Ensuring System Stability and Safety

With real-time feedback on critical density parameters, these meters support stable system operation, reducing the risk of equipment damage or process interruptions. Additionally, they minimize human exposure to hazardous materials by eliminating the need for frequent manual sampling in potentially dangerous environments.

Recommended Products & Corresponding Advantages

No. 1 Tuning Fork Density Meter

It is ideal for slurries like those found in wet desulfurization processes. They provide continuous real-time density measurement, and feature easy direct-insertion installation. Their robust design reduces maintenance costs and increases system reliability, making them suitable for industrial biogas applications

Tuning Fork Density Meter

No. 2 Ultrasonic Density Meter

The meter is compatible with various applications, including chemical production. Their robust design, compatibility with corrosive fluids, and digital data outputs make them valuable for monitoring biogas desulfurization systems.

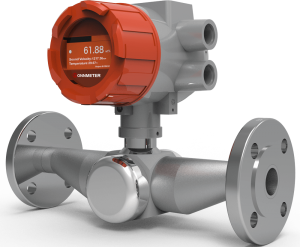

No. 3 Coriolis Flow Meter

While primarily Coriolis flow meters, they can also measure density with high accuracy in processes involving liquids with varying densities. They are reliable for biogas desulfurization where precise control of the chemical reaction is essential.

The solution for biogas desulfurization should emphasize the pivotal role of industrial automation and precision control in optimizing the process. By implementing real-time monitoring tools, such as inline density meters, industries can effectively manage desulfurization liquid concentrations to ensure high efficiency and system stability. This not only prevents equipment corrosion and blockages but also reduces operational costs and enhances environmental compliance by minimizing harmful emissions like hydrogen sulfide.

Moreover, automating the desulfurization process significantly reduces labor intensity, increases safety, and ensures continuous, reliable operation. Precision control of the desulfurization liquid enables fine-tuning of reaction conditions, ultimately improving energy utilization and the quality of biogas. These advancements represent a leap forward in sustainable industrial practices, aligning with modern energy goals and environmental stewardship.

Post time: Dec-31-2024