Accurate and stable concentration of cutting fluids is beneficial to extensive life and quality of tools produced from metalworking. And it turns unexpected breakdowns a thing of the past. The secret to realize the vision often rests on an overlooked factor -- precise concentration control over cutting oil.

What is Cutting Fluid?

Cutting fluid refers to a kind of coolant or lubricant, aka cutting oil, cutting compound, formulated specifically for metalworking processes like machining and stamping. There are several cutting fluids varied in status and components, such as oils, oil-water emulsions, pastes, gels, aerosols, air and other gases. In general, they are made from petroleum distillates, animal fats, plant oils, water and air, or other raw ingredients.

Functions over Precise Control of Cutting Fluids

Correct and precise concentration of cutting fluids is critical for improving machining efficiency, tool performance and even product quality. It also serves in the following aspects like cooling, lubrication, flushing, etc.

Intense heat is triggered by friction between the tool and workpiece in cutting. Cutting fluids at a required concentration is able to dissipate the heat efficiently while preventing thermal damage to both the tool and workpiece. Furthermore, adequate lubrication works in minimizing frictions before generating intense heat, achieving smoother surfaces and tighter tolerances on finished parts.

Cutting fluids formulated at a correct concentration contributes to chip removal and debris from the cutting zone, reducing potential risks of chip buildup as keeping operational efficiency. As earlier preferred, oil-based cutting fluids at balanced concentrations form a protective layer on metal surfaces, which prevents rust and corrosion naturally and extends the lifespan of tools and machined workpieces.

Best Cutting Fluid Concentration Meters

Fork density meter works through measuring changes in the frequency of a vibrating sensor immersed in the fluid, an ideal option for real-time concentration monitoring for its accuracy and stability.

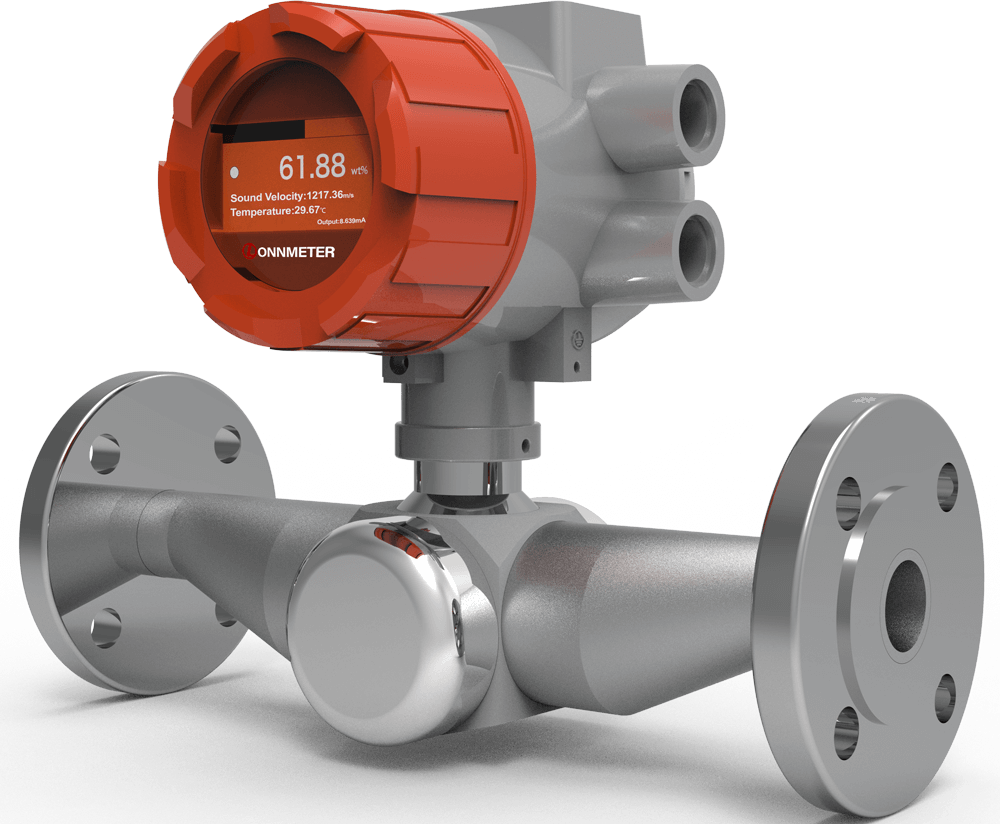

An ultrasonic density meter determines fluid concentration or density by measuring the time it takes for sound to travel through the liquid.

An optical refractometer measure the refractive index of the fluid, which correlates with its density and concentration. It's an ideal option for fluids with transparent or semi-transparent properties.

Benefits of Integrating Inline Density Meter

Real-time monitoring and automatic adjustment reduces production intervals and shutdown caused by cutting fluids, improving production efficiency and the whole utilization of devices. In addition, it extends the lifespan of both production equipment and final products. Contact Lonnmeter sales team for detailed parameters or request a free quote for your production line to elevate the automatic level.

Post time: Jan-15-2025