Pressure Measurement Solutions

What Are Inline Pressure Transmitters?

Inline pressure transmitters are devices linked to process equipment to measure pressure of gases or liquids, ensuring continuous, accurate pressure readings without needs for bypass lines and repetitive manual sampling. They transform pressure into an electrical signal for process control and monitoring, especially essential for safe and efficient operations in pipelines, reactors and systems. Apply robust online pressure transmitters to precise and real-time pressure monitoring across diverse applications.

Why Choose Lonnmeter Pressure Transmitters?

Lonnmeter employ themselves in providing state-of-the-art pressure transmitter solutions to tackle challenges of modern industry. Empower industries like oil & gas, chemical processing, power generation, and pharmaceuticals to optimize processes, enhance safety, and ensure compliance with intelligent pressure transmitters. Cooperate with the pressure transmitter supplier for continuous pressure measurement.

Applications of Our Pressure Transmitters

Oil & Gas

Monitor pipeline and wellhead pressure for safe and efficient operations in upstream and midstream processes. Our transmitters handle high-pressure and hazardous environments, ensuring compliance with standards.

Crude Oil

Gasoline

Disel

Kerosene

Lubricating Oils

Liquefied Natural Gas (LNG)

Liquefied Petroleum Gas (LPG)

Sour Gas

Sweet Gas

Carbon Dioxide (CO₂)

Nitrogen (N₂)

Methane (CH₄)

Ethane (C₂H₆)

Ammonia (NH₃)

Chemical Processing

Control pressure in reactors and distillation columns, even with corrosive or high-pressure fluids. Lonnmeter transmitters feature 316L stainless steel or Hastelloy for durability and precision.

Sulfuric Acid (H₂SO₄)

Hydrochloric Acid (HCl)

Sodium Hydroxide (NaOH)

Nitric Acid (HNO₃)

Acetic Acid (CH₃COOH)

Benzene (C₆H₆)

Synthesis Gas (Syngas)

Sulfur Dioxide (SO₂)

Steam (Water Vapor)

Propylene (C₃H₆)

Ethylene (C₂H₄)

Oxygen (O₂)

Pharmaceuticals

Ensure precise pressure monitoring in sterile environments for regulatory compliance. Our sanitary transmitters meet FDA standards, ideal for reactor and cleanroom applications.

Power Generation

Measure steam or gas pressure in boilers and turbines to ensure operational safety and efficiency. Our transmitters support high-temperature and high-accuracy requirements for power plants.

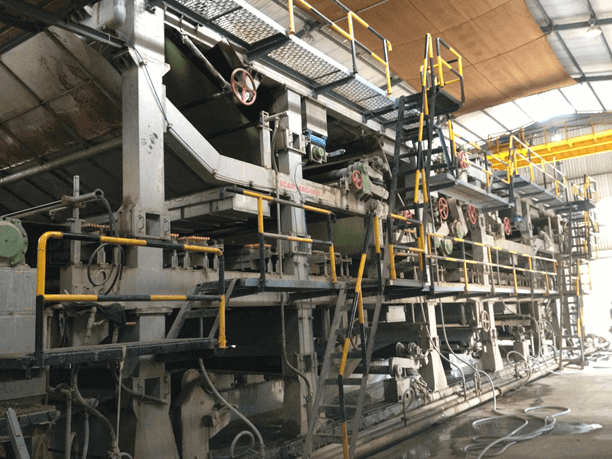

Pulp and Paper Industry

Monitoring pressure in digesters or pulp refining processes. Measuring pressure in steam lines for paper drying. Controlling pressure in chemical recovery systems.

Challenges and Solutions in Pressure Measurement

◮ Drift is caused by temperature fluctuations or improper installation in general. Dynamic compensation system is equipped with temperature sensor to realize real-time temp monitoring of ambient or equipment.

◮ Clogging in tank or pipelines is triggered by buildup of solid particles, viscous media, precipitated crystals and condensed material. Scientific mechanical design -- no moving parts of pressure transmitters lower risks of clogging.

◮ Electrochemical and chemical corrosion occur in pressure measuring of corrosive fluids or water featuring dissolved oxygen. Select anti-corrosion material like Titanium, Hastealloy, ceramic and nickel alloy to withstand harsh environments.

◮ Balance accuracy needs with budget; gauge pressure transmitters are often cheaper than absolute.

Benefits of Inline Pressure Transmitters

Improve accuracy for reliable process control;

Build pressure sensors with tailored robust material;

Achieve seamless compatibility with versatile interfaces like 4-20 mA, HART, WirelessHART, and Modbus;

Simple mechanical structure reduce cost of regular maintenance.

Partner with Lonnmeter

Integrate mass production equipment with intelligent pressure transmitters for optimal innovation and consistent quality control. Reduce risks of equipment wear, corrosion, clogging and operational costs.